Cement Production

Understanding the complete process of cement manufacturing and quality control

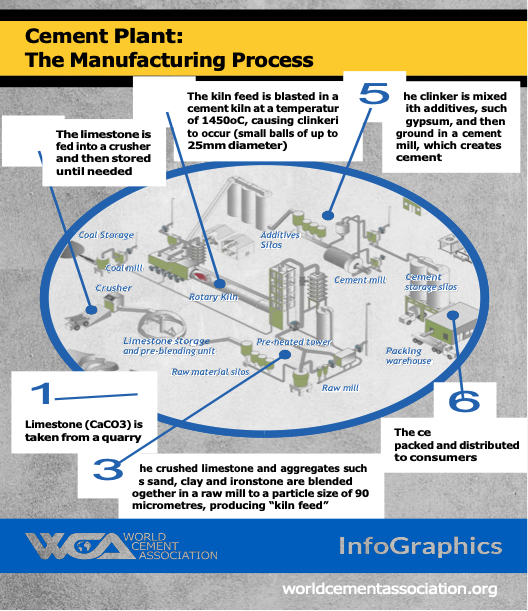

Cement Manufacturing Process

The complete cement production process consists of 8 main stages

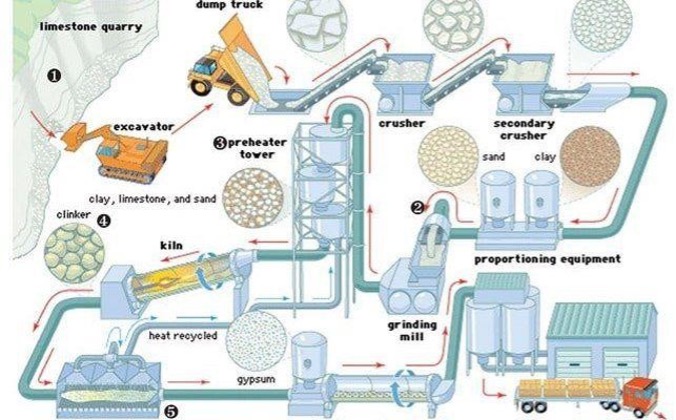

Quarrying and Crushing

Raw materials (limestone and shale) are mined from quarry 0.7km away and crushed to required size using specialized crushers.

Raw Material Storage

Crushed materials are stored and pre-homogenized using stackers and reclaimers for consistent quality.

Proportioning

Raw materials are proportioned based on chemistry analysis and sent to grinding unit every hour.

Raw Material Grinding

Materials are ground to fine powder (90μm) using ball mill or VRM while being dried with hot gases.

Raw Meal Storage

Ground raw meal is stored and homogenized in silos to ensure chemical consistency for kiln feeding.

Pyroprocessing

Raw meal is heated, calcined at high temperature (1450°C) in rotary kiln to form clinker, then cooled and stored.

Cement Grinding

Clinker is ground with gypsum and additives to produce different types of cement (OPC, PPC, PLC, LHHS).

Packing and Dispatch

Finished cement is packed in 50kg bags or dispatched in bulk form for distribution to customers.

Detailed Manufacturing Stages

Quarrying and Crushing

The quarry is located 0.7 km from the plant and provides the main raw materials:

- Limestone (provides calcium oxide)

- Shale (provides silicon and aluminum oxides)

- Iron ore, silica sand (corrective materials)

- Gypsum and pozzolana (for final grinding)

Line 1: 1000x1000x1500mm → ≤25mm (85%)

Line 2: 1000x1000x1500mm → ≤75mm (90%)

Raw Material Storage and Transportation

The plant has three raw material storages strategically organized for both production lines:

Storage 1 (Line 1)

Stores: Limestone, Shale, Silica sand, Iron ore, Pozzolana, Gypsum and limestone additive

Storage 2 (Line 2)

Stores: Limestone and Shale

Storage 3 (Line 2)

Stores: Correctives (Silica sand, Iron ore) and Additives (Pozzolana, Gypsum, Limestone additive)

Homogenization Process:

- Stackers create material piles with homogenization effect

- Reclaimers and belt conveyors transport materials to proportioning bins

- Loaders are used for correctives and additives (especially Line 1)

Precise Material Proportioning

Proportioning

In this unit, Limestone, Shale, Silica sand and Iron ore are proportioned and sent to Raw mill Unit for grinding. The proportioning ratio is done/adjusted every hour.

Automated Quality Control

The proportioning ratio is adjusted hourly through:

- Weigh feeders beneath each bin communicate real-time data

- QCX software (Blending Expert) analyzes and optimizes ratios

- X-ray analysis every hour of raw materials (input to grinding)

- X-ray analysis every hour of raw meal (output from grinding)

High-Precision Grinding

Raw Material Grinding and Transportation

In this unit, the proportioned raw materials are being ground to the size of (10% residual on 90 μm sieve).

Line 1

Closed Circuit Ball Mill

Line 2

Vertical Roller Mill (VRM)

Simultaneous Drying:

While grinding, raw materials are dried from 4% moisture content to <1% using excess hot gas emitted from the pyroprocessing system.

Process Efficiency:

- Fineness: 10% residual on 90μm sieve

- Energy recovery: Uses hot gases from kiln

- Moisture reduction: 4% → <1%

Silo Storage & Homogenization

Raw Meal Storage, Homogenization and Kiln Feeding

In this unit, the raw meal which is ready for burning process is stored and homogenized in a storage called SILO.

Quality Assurance

The SILO ensures that the standard deviation of the raw meal chemistry is within acceptable range suitable for:

Pyroprocessing

The heart of cement manufacturing where clinker is formed through high-temperature chemical reactions:

Preheater

Raw meal is preheated and dried using hot gases

Calciner

95% of CaCO₃ decomposes to CaO + CO₂

Rotary Kiln

Remaining 5% CaCO₃ decomposes and clinker minerals form at 1450°C

Cooler

Hot clinker is rapidly cooled and crushed

Line 1: 2,100 tons/day

Line 2: 3,500 tons/day

Cement Types Produced

OPC

Ordinary Portland Cement

Clinker + GypsumPPC

Portland Pozzolana Cement

Clinker + Pozzolana + GypsumPLC

Portland Limestone Cement

Clinker + Limestone + GypsumLHHS

Low Heat High Strength

Special Clinker + GypsumPrecision Cement Grinding

Cement Grinding and Storage

In this unit, the input materials (Clinker, Gypsum, Pozzolana, and Limestone additive) are proportioned and ground in Cement mill based on the type of cement to be produced.

Line 1

One Closed Circuit Ball Mill

Line 2

Two Roller Press + Closed Circuit Ball Mill

Cement Type Formulations:

- PPC: Clinker + Pozzolana + Gypsum

- OPC: Clinker + Gypsum

- PLC: Clinker + Gypsum + Limestone

- LHHS: Special Clinker + Gypsum

Cement Packing and Dispatch

In this unit, the finished product (cement) from the storage silo is transported and packed using modern Ventomatic GEV/8 packers.

Line 1

- 2 Packers

- 4 Loading Bays

- 2,000-2,500 bags/hour per packer

Line 2

- 4 Packers

- 8 Loading Bays

- 2,000-2,500 bags/hour per packer

Packaging Options:

- 50kg polypropylene bags (standard)

- Bulk cement loading in powder form

- Big bags (2 ton capacity)

Environmental Control

Note: In each of the above units (1-8), cyclones and bag filters are used to control dust emission to the environment to keep the emission level below 30mg/Nm³, ensuring compliance with environmental standards.

Process Control

All operations are monitored and controlled from a Central Control Room (CCR) using advanced automation systems.

-

DCS & PLC Systems

Distributed Control System for automated process management

-

PIDs & Display Mimics

Real-time monitoring of all process parameters

-

CCTV Monitoring

Visual surveillance of critical areas

-

Expert Team

Experienced cement technologists and engineers

Quality Control

Messebo Cement Factory Quality Control Laboratory

Messebo QC Testing Methods

Two complementary testing approaches for comprehensive quality assurance

Dry Method Testing

Advanced XRF analysis for rapid and precise chemical composition testing.

- Panalytical XRF

- Thermofisher XRD-XRF

- QCX & QCS Blending Software

- Hourly analysis for process control

Wet Method Testing

Traditional chemical analysis for cement, clinker, and raw materials.

- Volumetric (Titration) Analysis

- Gravimetric (Weight) Analysis

- Free-lime Testing

- Chemical Composition Verification

Quality Testing Equipment

State-of-the-art laboratory equipment for comprehensive quality analysis

XRF Machine

Elemental chemical analysis of raw materials

Bending & Compression Machine

Test cement strength (ES EN 197-1 standard)

Le-Chatelier Apparatus

Test cement soundness and expansion potential

Blain Apparatus

Measure cement fineness during milling

Vicat Apparatus

Test cement setting time and workability

Bomb Calorimeter

Measure coal gross calorific value

Differential Calorimeter

Measure cement hydration heat

Environmental Control

Dust emission control systems ensure environmental compliance.

- Cyclones for particle separation

- Bag filters for dust collection

- Electrostatic precipitators

- Heat exchangers for gas cooling

Clean Air Systems

Advanced filtration technology for minimal environmental impact